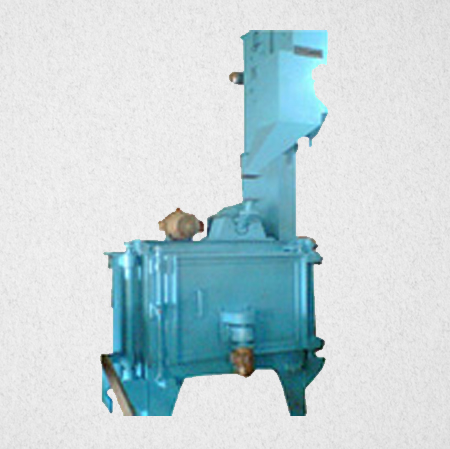

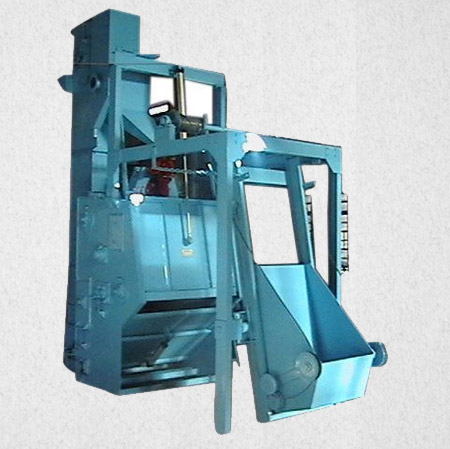

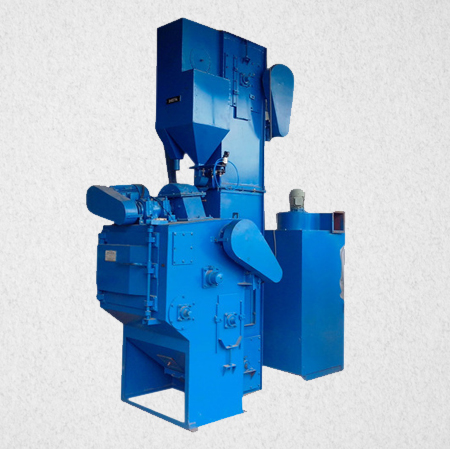

Shot Blasting Machines

| • | Shot Blasting Machines |

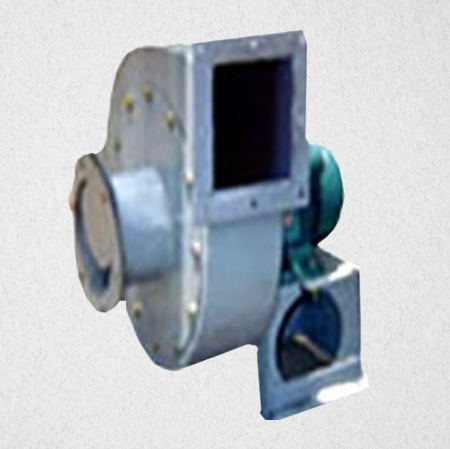

• | Dust Collector Systems |

|---|---|---|---|

| • | Shot Peening Machines |

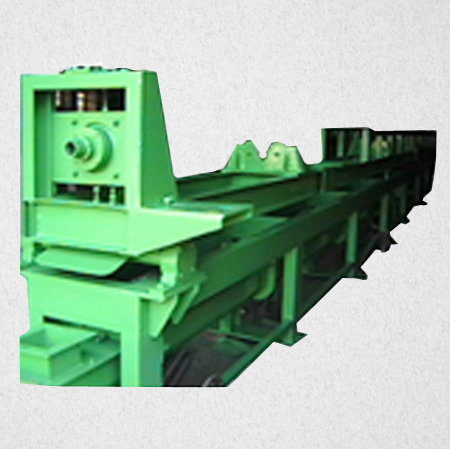

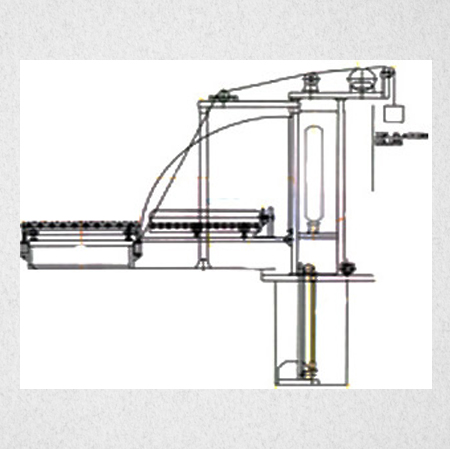

• | 90 Degree Turn Conveyors |

| • | Roller Conveyors |

• | Cyclones |

| • | Bucket Elevators |

• | Tumblast Type Shot Blasting Machines |

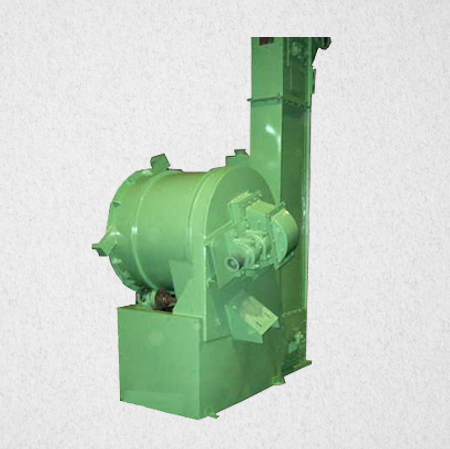

| • | Exhaust Blowers |

• | Fully Automatic TUMBLAST Type

Shot Peening Machines |

| • | Foundry Machineries |

• | Sand Blasting Machines |

| • | Spares for Shot Blasting Machines |

• | Shot Blasting Machine For PAVOR BLOCKS 80 PICES / HR. |

We make 4 types of models :

• Glint-350 : Hanger size 700 x 900 Double Door

• Glint-450 : Hanger size 800 x 1000 Double Door

• Glint-800 : Hanger size 1000 x 1500 Double Door

• With compartment indexing type useful for small Gears & forging.

• Tumblast type

Above type machine is suitable for small jobs which cannot be hanged, High producing Volume, low maintenance. We make two type of this machines.

20" x 27" (2 CFT) & 27" x 36" (4 CFT) Special design 1st time introduced bu us

• Internal shot blasting machine for cylinders.

• External shot blasting machine for pipe & cylinder.

• Special purpose shot blasting & shot peening machines for gears, pinions, strips etc.

• Roto moulding machines for plastic water tanks.

• Pulverisers for making powder from plastic granules upto cap. 70kg / hr.

Shot Blasting Machines, Shot Peening Machines, Material Handling Equipments, Blowers, INTERNAL and external short blasting machine for cng cylinders and Oxygen cylinders and special purpose machines

AUTOMATED SURFACE TREATMENT MACHINERY.

Shot Peening, Shot Blasting, Blast Room, External Blast Cleaning of cylinders. Internal Blast Cleaning of cylinders. Tube Blast Cleaning Machines.

As the technology available to analyze the results of peening efforts evolves,wet end to focus on factors such as micro structure, X-ray diffraction,shot shape, shot hardness, part distortion stress analyzes to name a few.

All of above are very significant and necessary studies, but what about the novice shot peener or the company that may have recently obtained its first Shot Peening Machine?

For the novice, a good foundation will follow a methodical common sense approach to the task. The key point at this stage is for the people to

understand the relationship between the equipment and the outcome of peening cycle.

WHEEL SPEED / Air PRESSURE = SHOT VELOCITY = INTENSITY

SHOT FLOW * TIME = COVERAGE.

This is also critical when a different intensity or coverage is required warranting adjustments to the technique.

1. Establish velocity required to reach the target intensity by adjusting wheel speed oe Air pressure.

2. Find optimal shot flow rate corresponding to wheel speed / Air pressure required

3. Develop saturation curve and set intensity

4. Determine time required to achieve 98 % - 100 % coverage on part.

5. Expose parts to shot stream to achieve % coverage requested ( 100%, 150% etc.)